Consultex Systems was founded in Spartanburg, SC, in 1974. We began selling textile machine parts which evolved into a full manufacturing operation. Consultex Systems focused on coating systems through quality, innovation, and personalized service.

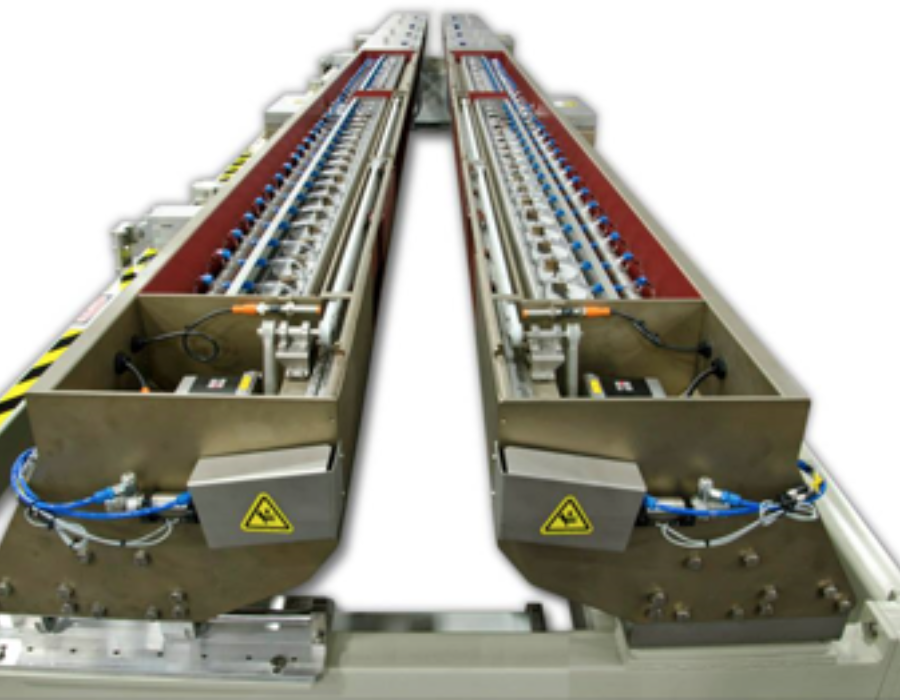

The Patented IQ Rotary Spray design developed into one of the leading coating systems serving the textile, nonwovens, film, rolled steel, tissue, paper, and particle board industries. Through continued investment in research and development, Consultex engineers designed coating machines for standard applications spraying water or water-based chemicals on vertical webs. Additionally custom solutions are available other proprietary applications to meet specific customer needs. Look for information on our pilot line described nearby.

In 2018, Consultex Systems joined the Navis Tubetex group of brands and moved their operations to Lexington, NC. Since partnering with Navis Tubetex, Consultex products continue to innovate. As water and chemical saving become more critical, the technology becomes more relevant. Plus as new processes emerge, we are seeing new applications perfectly suited for rotary spray. Look for our newly developed products for digital print applications among others.